News 09 December 2025 News

Lignin-Based Composites: Unlocking a Sustainable Future for Construction and Mobility

As industries worldwide push toward circular and low-carbon materials, bio-based composites are emerging as a powerful opportunity for sustainable innovation. Within this framework work was carried out in the Eurostars project “Fully Bio- and Waste-based Composite with High Added Value” which focuses on transforming underused bio-resources into high-performance, market-ready composite solutions.

Lignocellulosic materials mainly consist out of cellulose, hemicellulose, and lignin. Cellulose is used for paper industry leaving hemicellulose and lignin as as by-products representing an abundant and renewable resource of millions of tons. Despite their availability, they are often underutilized or burned for low-value energy recovery. By converting these bio-based side streams into structural composite components, the project addresses longstanding waste-management challenges while creating new pathways for high-value applications in the construction and mobility sectors.

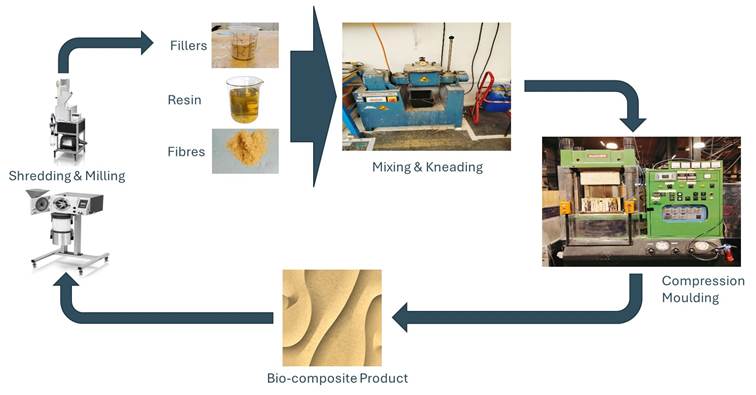

Using Bulk Moulding Compound (BMC) technology, the project combines lignin-based resin, lignocellulosic fillers, and fibres into a mouldable dough. When pressed at 140–160°C and 70–90 bar, the material cures into strong composite panels suitable for demanding end-use applications.

Figure 1: BMC Manufacturing process

Real-World Demonstrators: From Lab to Implementation

One of the project’s major achievements while collaborating with our Swedish partner LigniCore was the successful production of temporary traffic signs, which were installed in Sweden by Provia and tested by Trafikverket. These real-world demonstrators confirmed the technical feasibility of lignin-based composites and generated genuine commercial interest.

Beyond mobility solutions, the project also developed lignin-based façade panels to meet the growing demand for low-carbon, bio-based materials in the construction sector. These panels have the potential to partially or fully replace aluminium and other high-impact materials in façade elements, electrical housings, and signage.

From Lab Scale to Industrial Readiness

Initial material development was carried out at a scale of 500–600 g, limited by laboratory equipment. After formulation and process optimization, multiple manufacturing technologies were evaluated. A major milestone was reached when successful mixing was achieved, demonstrating feasibility for industrial scaling. Since NPSP operates similar 1000 kg mixers, the transition toward commercial production is realistically within reach. Fire-performance tests on the fully bio-based composites delivered promising early results. Further testing will be necessary to qualify the materials for stringent building and transport applications, offering a clear direction for future research.

A Circular Approach: Mechanical Recycling of Lignin Composites

Traditional composite waste streams often end in landfilling or incineration. This project instead prioritized mechanical recycling as a sustainable end-of-life route.

Two types of panels were evaluated:

- industrial recycling, the recycling of C-choice products and missprints

- panels aged in an accelerated weathering chamber for two months

Both were milled to <125 µm and reused as fillers in new BMC formulations, replacing virgin lignocellulosic fillers.

The results were highly encouraging, with recycled-filled BMCs showing:

- Greater flexural strength,

- Greater flexural strain,

- Comparable flexural modulus.

These results show that mechanically recycled fillers can match - or even outperform - virgin alternatives, offering a realistic path toward closed-loop composite manufacturing and improved Life Cycle Assessment (LCA) performance.

Conclusion: Strong Potential with a Clear Path Forward

Lignin-based composites demonstrate the potential to replace a wide range of materials in both construction and mobility sectors. Continued development will focus on improving both the resin chemistry and the BMC formulation to further enhance performance.

Next Steps: Toward Commercialization

Ongoing collaboration with LigniCore will address the remaining challenges, including:

- improving durability and long-term performance,

- further fire-performance evaluation,

- increasing the bio-based content, and

- exploring interactions with coatings and pigments.

Together, these developments form the next crucial milestones on the path toward full commercialization of bio- and waste-based composite materials.

The research was financially supported from within the Eurostars programme by Rijksdienst voor Ondernemend Nederland (RVO) and Vinnova from Sweden. Partners outside the project were Södra and Trafikverket.